EDDYFI LYFT

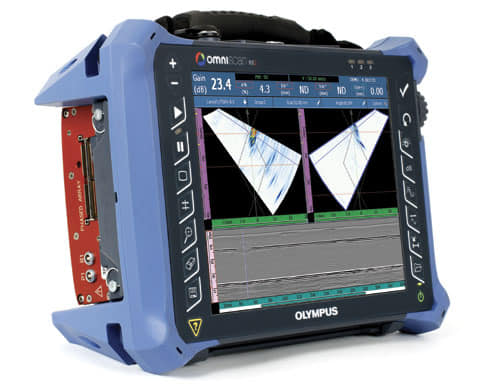

EddyFi Lyft — a reinvented, high-performance PEC solution. The system features a portable, state-of-the-art instrument, real-time C-scan imaging, fast data acquisition (up to 15 readings per second) with grid-mapping and dynamic scanning modes, and flexibility with long cables (35 m / 115 ft). It can also scan through thick metal (up to 64 mm / 2.5 in) and insulation (up to 203 mm / 8 in liftoff), as well as aluminum, stainless steel, and galvanized steel weather jackets.

The Lyft software is packed with automation and advanced algorithms that remove operator-specific dependence, thanks to the power of the SmartPULSE technology. It automatically optimizes pulser and receiver parameters (gain, duration, time gates, filters, etc.). SmartPULSE also optimizes wall thickness (WT) measurements, which ensures optimum performance and repeatability, while limiting the need for advanced knowledge of pulsed eddy current.

The multi-touch, user-friendly software includes several innovative features, including real-time C-scan imaging (grid mapping and dynamic modes), complete WT measurements (ID and OD corrosion), as well as complete inspection management and reporting capabilities.

The Lyft instrument is sealed and designed for IP65. Its magnesium alloy casing is tough, water and dust resistant, and cools without any external air exchange. The adjustable stand, the top handle, and four corner anchor points make it practical for on-site inspections. The embedded and portable Windows PC offers standard connect-anywhere capabilities and advanced productivity tools that optimize field testing. The premium-quality 26.4 cm (10.4 in) LED display is optically bonded, non-reflective, comes with 3 mm (1/8 in) strengthened glass, and is designed for gloved hands, under any lighting conditions. The system also comes with two, hot-swappable batteries for extended battery operation.

CUI Programs Redefined

Corrosion Under Insulation (CUI) is possibly the greatest unresolved asset integrity problem in the industry. Current methods for measuring wall thickness over insulation (Liftoff) without removing it all have severe limitations. Lyft® is a high-performance solution reinventing Pulsed Eddy Current

Lyft can scan through thick insulation, as well as aluminum, stainless steel, and galvanized steel weather jackets. It also benefits from a range of PECA, single-element PEC, and application-specific probes to support various applications. Who else but Eddyfi would reinvent an eddy current technique, integrate high-productivity array to the solution and completely redefine CUI programs?

Benefits

• Inspect through thick insulation and fireproofing

• Save on insulation removal costs

• Real-time imaging for instant results

• Unrivalled productivity with PECA

• Easy setup with SmartPULSE calibration

• Highest confidence with Tau-scan and PermTool advanced analysis tools

• Elevated team collaboration and support with Zoom integration

• Ensure secure and efficient data management through OneDrive integration

• Craft crystal-clear and context-rich reports effortlessly with seamless integration via Eddyfi mobile application

Applications

• Corrosion under insulation (CUI) and fireproofing (CUF)

• Insulated pipes and vessels

• Through aluminum, stainless steel, and galvanized steel weather jackets

• Safe, in-service scab corrosion assessment with no need to remove corrosion product

• In-service inspection of storage tank annular plates

• Underwater and splash zone structures

• Ship deck inspections through tiles and coatings

INSTRUMENTS

- 355 × 288 × 127-mm (14.0 × 11.3 × 5.0-in)

- 6.6 kg (14.5-lb)

- 7 (GDA)

- 26.4-cm (10.4-in)

- Multi-touch

- Non-reflective (AR coating)

- Anti-fingerprint (oleophobic coating)

- 3-mm (0.125-in), chemically strengthened glass cover

- Optically bonded LCD and touchscreen

- Passive blacklight enhancement

- Gigabit Ethernet, Wi-Fi™, Bluetooth, 3 × USB 2.0

PERFORMANCE

- Up to 15 points/s

- 75-mm/s (3-in/s) (Typical), subject to variations based on component specifications and acquisition parameters.

- Instant, less than 1 second (typical)

- Automatic configuration of PEC pulser-receiver parameters

- Full thickness sensitivity (OD and ID flaw detection)

- Reliable measurements even with liftoff variations, weather jacket overlaps, straps, and corrosion scabs

- Repeatability optimization

- One-point calibration (on nominal wall or known thickness value) and auto-normalization

There are no reviews yet.